Few things are more frustrating for a truck driver than hitting the road and realizing your truck isn’t building air pressure. Without proper air pressure, your brakes and air systems won’t function — and that means you’re stuck.

One often-overlooked culprit is the air compressor discharge line. When this line is clogged or blocked, it can mimic compressor failure or a major leak, leaving drivers scratching their heads. At Sam’s Services, we’ve seen this problem many times — and we know how to diagnose it correctly without wasting time or replacing unnecessary parts.

In this article, we’ll explain why air compressor discharge line problems happen, the warning signs to look out for, and how to prevent costly breakdowns.

What Is the Air Compressor Discharge Line?

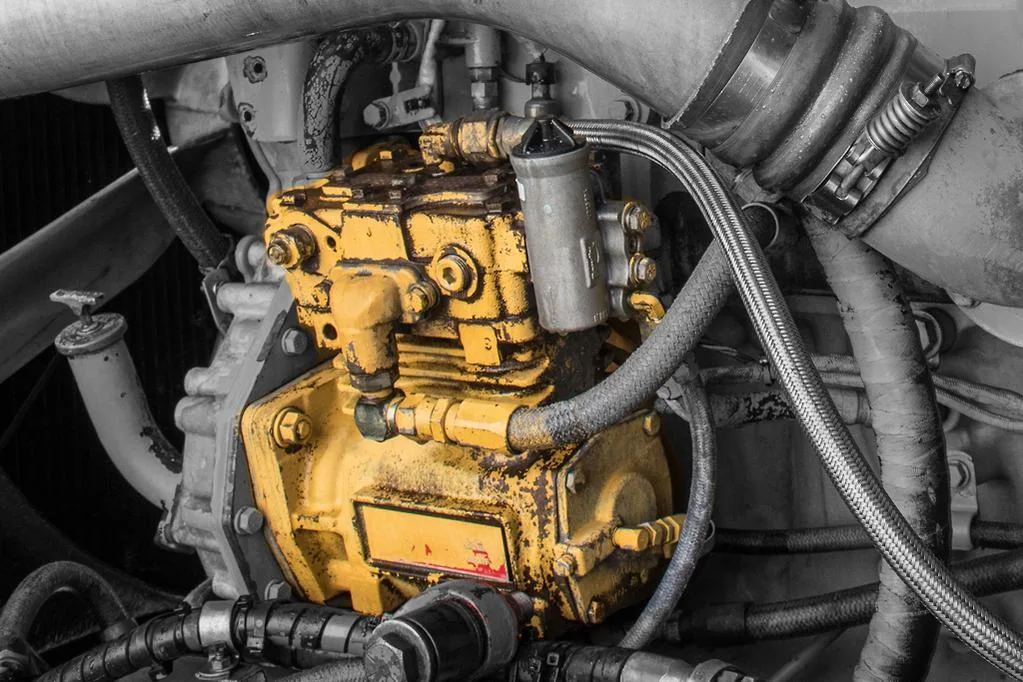

The air compressor discharge line is the hose or pipe that carries hot, compressed air from the truck’s compressor to the air dryer.

Its role is critical:

It moves compressed air into the dryer, where moisture and contaminants are removed.

It keeps the system flowing so pressure can build and stabilize.

It acts as the “bridge” between compressor function and overall brake system operation.

If this line becomes blocked, the compressor may still be working, but the air can’t get through. The result? Your truck won’t build pressure — leaving you sidelined.

Real-World Example: A Truck That Wouldn’t Build Air

Recently, our techs were called out to assist a driver whose truck wouldn’t build air. At first, it seemed like a simple no air build issue — possibly a bad compressor or major leak.

Here’s how our team diagnosed it:

Checked for leaks – No external air leaks were found.

Verified compressor function – The compressor was running and producing pressure.

Inspected the discharge line – When removed, the line was completely clogged with carbon buildup.

Once the blockage was cleared, the system built pressure normally. This saved the driver from replacing a perfectly good compressor — and got him back on the road quickly.

Why Air Compressor Discharge Lines Get Clogged

Clogging and blockages in the air compressor discharge line usually happen gradually. Over time, heat, oil, and poor routing combine to create carbon buildup inside the line.

Common Causes of Blocked Discharge Lines

Excessive Heat – When compressors run hotter than normal, oil vapor carbonizes inside the line.

Oil Carryover – Worn compressors can push oil into the line, which bakes into carbon deposits.

Improper Routing – If the line is too short, too long, or incorrectly routed, cooling is reduced — leading to buildup.

Neglected Air Dryer Service – An overdue or plugged dryer puts more strain on the system.

Symptoms of Air Compressor Discharge Line Problems

Recognizing the signs of a blocked air compressor discharge line can save you hours of downtime.

Truck won’t build air pressure.

System pressure fluctuates abnormally.

Air dryer performance is poor.

Compressor seems fine, but the system still fails to pressurize.

These symptoms often mimic compressor or valve issues, which is why a proper diagnosis is essential.

The Hidden Cost of Ignoring Discharge Line Issues

Ignoring a clogged air compressor discharge line isn’t just inconvenient — it’s costly.

Unexpected Downtime – Drivers can be stranded roadside.

Unnecessary Repairs – Many compressors get replaced when the line was the real problem.

Brake Safety Risks – Without pressure, brake systems can’t operate.

Higher Maintenance Costs – Neglected lines put strain on the entire air system.

If ignored, this small line can take your entire truck out of service — a risk no fleet or owner-operator can afford.

Roadside Support You Can Count On

No matter the situation, our reliable roadside assistance ensures you get the help you need, fast. From breakdowns to emergencies, we’re here 24/7 to keep you moving.

How to Fix a Blocked Air Compressor Discharge Line

The good news? Once diagnosed, a clogged air compressor discharge line is straightforward to fix.

Remove the line and inspect for buildup.

Clean or replace the line if necessary.

Check routing to ensure proper cooling.

Service the air dryer to prevent future problems.

Test the system to confirm pressure builds normally.

At Sam’s Services, our technicians don’t guess — we diagnose. That means less downtime, fewer unnecessary parts, and more reliable results.

Preventing Air Compressor Discharge Line Failures

Preventive maintenance is the key to keeping your air system reliable. Here are some best practices:

Inspect discharge lines regularly for heat damage or buildup.

Service air dryers on schedule to reduce strain.

Monitor compressor performance for signs of overheating or oil carryover.

Verify proper routing of discharge lines after repairs.

Perform thorough pre-trip inspections to catch issues early (see our blog on pre-trip inspection importance).

Why Choose Sam’s Services for Air System Repairs?

At Sam’s Services, we specialize in diagnosing and repairing problems that others often overlook. Whether it’s a blocked discharge line, a failing dryer, or a full roadside repair, we get the job done right the first time.

24/7 Roadside Assistance – We respond quickly anywhere in Houston.

Experienced Technicians – Our crew is trained to spot hidden issues.

Comprehensive Services – From trailer repairs to towing and recovery, we cover it all.

Proven Results – We save drivers from unnecessary costs by finding the real cause of the problem.

Keep Your Truck on the Road

Don’t let a clogged air compressor discharge line shut you down. At Sam’s Services, we provide fast, accurate diagnostics and repairs that keep your truck moving safely.

👉 Request Service Now or call our 24/7 team for immediate roadside help.

Frequently Asked Questions

Blockages usually come from excessive heat, oil carryover, poor line routing, or neglected air dryer service. Over time, carbon builds up until airflow is blocked.

If your truck isn’t building air despite a working compressor and no external leaks, the discharge line may be blocked with carbon buildup.

No. Without airflow through the discharge line, your system won’t build or hold pressure. Driving is unsafe and may damage other air system components.

Our team diagnoses and repairs air system failures, including blocked lines, air dryers, and compressors. We provide 24/7 roadside assistance and shop repairs in Houston.