When a truck air brake system starts hissing, many drivers and even some mechanics quickly point the finger at the ABS valve. After all, that’s often where the sound seems to come from. But here’s the truth: ABS valves rarely fail in a way that causes air leaks.

At Sam’s Services, we’ve seen countless trucks towed in or serviced roadside for “ABS valve leaks,” only to find the real culprit somewhere else in the brake system. This misdiagnosis costs drivers unnecessary money and downtime.

In this blog, we’ll break down why the ABS valve is often unfairly blamed, how to properly diagnose truck air brake leaks, and when to call the pros for roadside assistance in Houston.

Why the ABS Valve Isn’t Always the Problem

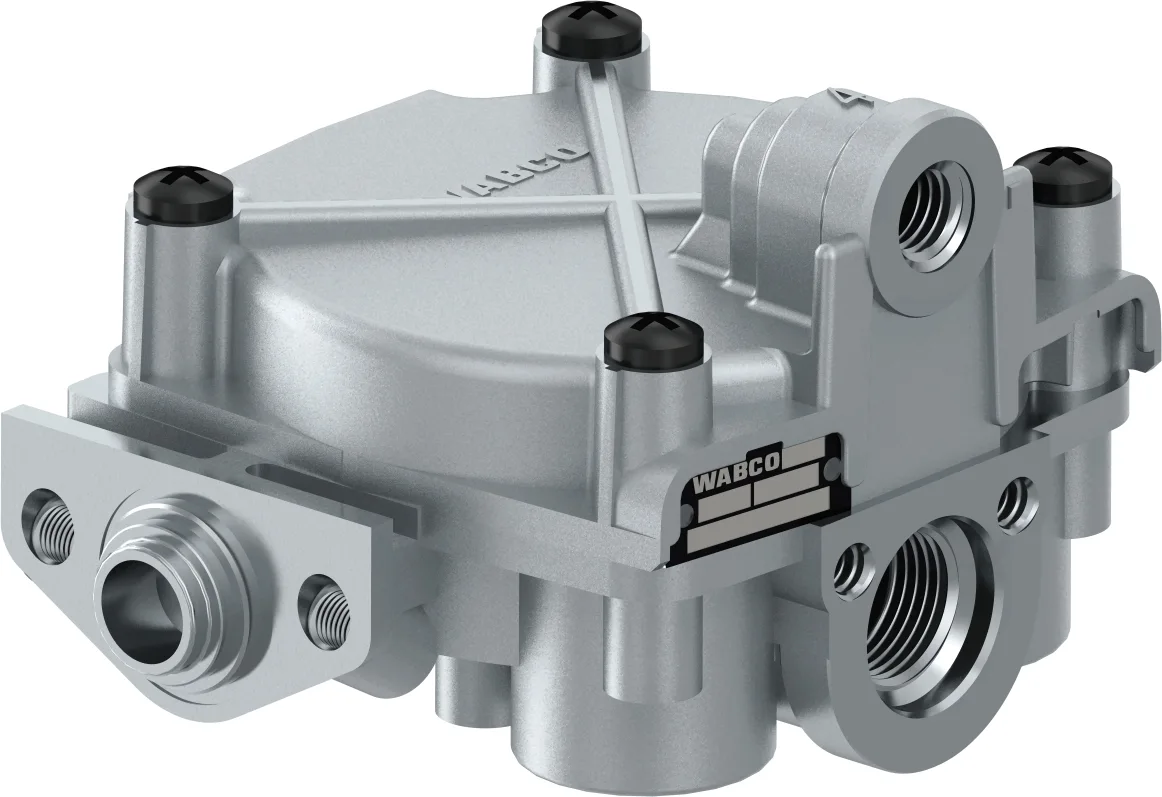

The ABS valve plays a critical role in controlling brake pressure during anti-lock braking events, but it has exhaust ports designed to vent air during normal operation. This is where the confusion comes in.

When other parts of the air brake system fail — such as a relay valve, brake chamber, or even a simple air line fitting — the escaping air often vents through the ABS valve’s exhaust port. That’s why the hiss is heard or felt at the ABS valve, even though it’s not actually the source of the leak.

In other words: the ABS valve is usually just the messenger, not the problem.

Common Causes of Air Leaks Mistaken for ABS Valve Issues

When you hear air at the ABS valve, don’t assume the valve is bad. The real issue is often elsewhere. Some of the most common culprits include:

1. Failing Relay Valve

Relay valves distribute air to the brake chambers. If a relay valve develops a leak, the escaping air can vent through the ABS valve’s exhaust ports.

2. Worn or Damaged Brake Chambers

Brake chambers are under constant stress. A ruptured diaphragm or damaged chamber can cause leaks that make it sound like the ABS valve is failing.

3. Loose or Cracked Air Line Fittings

Simple fittings and connections can be the weakest link. A cracked fitting or loose line can misdirect escaping air, which exits near the ABS valve.

4. Trailer-Related Leaks

Many drivers experience air leaks that are actually from the trailer brake system. Issues with the trailer relay valve or spring brakes often vent near the ABS system.

How to Properly Diagnose an Air Brake Leak

At Sam’s Roadside Service, our technicians never just guess and replace the ABS valve. Instead, we follow a step-by-step diagnostic process:

Listen and Trace the Sound – Instead of stopping where the hiss is loudest, we trace the airflow backward to its origin.

Check Brake Chambers – Inspect diaphragms and housings for cracks, bulges, or ruptures.

Test Relay Valves – Ensure relay valves are sealing properly and not releasing excess air.

Inspect Air Line Fittings – Tighten or replace damaged lines and fittings.

Confirm with Soap Solution – Spray suspected areas to visually identify leaks through bubbling.

This diagnostic process ensures the true source of the leak is found, instead of wasting time and money on an unnecessary ABS valve replacement.

Real-World Example from the Road

We recently helped a driver who was convinced their ABS valve was bad after hearing air escaping near it. They were ready to spend hundreds replacing the valve.

After inspection, our techs discovered the real problem: a leaking brake chamber diaphragm. The air had been venting through the ABS valve exhaust port, but the valve itself was working perfectly. Replacing the chamber fixed the issue and saved the customer from buying an expensive, unnecessary ABS valve.

This happens more often than you’d think — which is why proper diagnosis is critical.

Roadside Support You Can Count On

No matter the situation, our reliable roadside assistance ensures you get the help you need, fast. From breakdowns to emergencies, we’re here 24/7 to keep you moving.

Why Proper Diagnosis Saves Time and Money

Jumping to conclusions with brake leaks can lead to:

Unnecessary Parts Replacement – Wasting money on new ABS valves when the old one works fine.

Extended Downtime – Multiple repairs and re-diagnoses mean more time off the road.

Unsafe Operation – Ignoring the true cause of the leak can leave your brakes compromised.

Costly Towing Bills – Many misdiagnosed issues end up needing towing and recovery when the problem escalates.

At Sam’s Services, we pride ourselves on getting it right the first time — whether it’s at the roadside, in our mobile truck repair shop, or through a trailer repair.

The Role of ABS Valves in Modern Trucks

Even though the ABS valve isn’t usually the cause of air leaks, it’s still a vital component. ABS valves help:

Prevent wheel lockup during emergency braking

Maintain steering control under heavy braking

Distribute brake pressure evenly across axles

Improve safety in wet or slippery conditions

A healthy ABS system ensures compliance with modern DOT safety requirements and keeps both drivers and cargo safe.

When to Call Sam’s Services

If you’re in Houston and suspect an ABS valve air leak, don’t risk misdiagnosis. Call Sam’s Services for:

24/7 Roadside Assistance

Hazmat Clean-Up in case of spills

Cross-Docking for damaged or delayed loads

Whether it’s roadside or in-shop, our experienced techs will trace the real issue and get you back on the road quickly and safely.

FAQs – ABS valve

While possible, it’s very rare. Most of the time, air leaks blamed on ABS valves are actually caused by other brake system components.

True ABS valve failures typically show up as ABS warning lights or braking performance issues — not constant air leaks.

Inspect nearby brake chambers, relay valves, and air line fittings before assuming the ABS valve itself is the problem.

Not without a proper diagnosis. Replacing parts unnecessarily wastes money and doesn’t always fix the problem.